Smelting Experiments in 2015

This year’s three smelts in an experimental bloomery furnace, based on the Pippingford estate, have successfully produced three large blooms with two being successfully forged to produce billets [Figs.1a & 1b] of wrought iron that a blacksmith would use; the third bloom awaits the final smithing [Fig.1c].

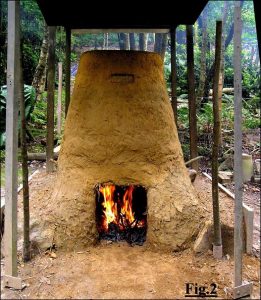

This did not happen without some problems: (1) the 2-hour-long time to pre-heat the furnace with charcoal to >750°C when smelting can start; (2) the temperamental generator [powering the blower], which is always stopping for some unknown reason. The latter has been solved by the purchase of a new, petrol, 4-stroke generator ready for next year’s smelts. The former problem of quickly pre-heating the furnace with charcoal must be resolved as it consumes excessive, expensive charcoal.The bloomery furnace being used [Fig.2], here shown being dried out after building, is a close copy of a Roman furnace discovered and excavated at Mayfield, Sussex. The furnace is supplied with locally dug iron ore, which, after roasting, is loaded into the top of the furnace along with an equal weight of charcoal, this is added in 2-Kg loads as the charcoal slowly burns down to make room. Molten slag is run out via the tapping arch; this is the non-metallic waste material from the impure ore. A “tuyere” is necessary whilst smelting, this is a pipe that extends into the furnace about 400-mm above ground level, through which air is blown to increase the working temperature to between 800 and 1000°C. After 5 to 6 hours of smelting a solid bloom [the iron is never molten!] is dislodged from the furnace wall and removed via the tapping arch [Fig.3]. The hot bloom is not usually weighed because its initial consolidation is better carried out straight from the furnace before the bloom cools. The larger the bloom the longer it takes to cool, with the hot iron centre glowing red through a crumbly surface of slag and charcoal, and is describe as “sponge-like” in ancient texts”. The first gentle hammering to consolidate the bloom is carried out using a mallet on a wooden anvil [Fig.4].

Further work is necessary before the bloom really looks like iron, called a billet, and is suitable for the blacksmith. After its initial hammering, the bloom cools and must be reheated. Due to its size and weight it is easier to re-heat it in a ground level forging hearth [Fig.5]. This can be built-up close to the furnace in a few minutes from fireproof bricks to form a horseshoe-shaped hearth ~700mm by ~1250mm, with the wall 300mm high through which a ~25mm diameter iron tuyere is fixed. The end of the hearth is open to give easy access for raking charcoal to and from the iron being forged. Now-a-days, blacksmiths uses a horizontal tuyere in a hearth fuelled by coke but when traditional charcoal fuel is used it is so light that it is blown away. But if the tuyere angled down ~30degs and the air reflected up from the ground towards the iron the charcoal is held in place by the iron. It is necessary for the air to pass through 50-75mm of hot charcoal to remove the oxygen [by producing CO & CO2 gas] which would otherwise oxidise the iron.

By far the hardest task is hammering the bloom into a billet of iron suitable for the blacksmith. If a crack appears in the iron it becomes necessary to fold the metal, at the crack to form a sandwich, and forge-weld it together; this is carried out by heating to an almost white heat and quickly hammering together, whereby it forms a seamless join; one of the many magic tricks that blacksmiths preform.

Brian Herbert© Wealden Iron Research Group 2015