In a move towards greater authenticity in our smelting experiments at Pippingford Park we have switched from our vortex blower, which supplies a constant flow of air, to an electrically driven reciprocating pump kindly denoted to WIRG by Peter Crew who conducted numerous experimental smelts using this in North Wales. Designed and built by Roger Miles, using a section of mains water pipe as the cylinder and a motor from a washing machine, the reciprocating pump better simulates blowing with bellows. This would have been the method used in early times, but requires a number of fit personnel to supply air for the duration of a day’s smelt.

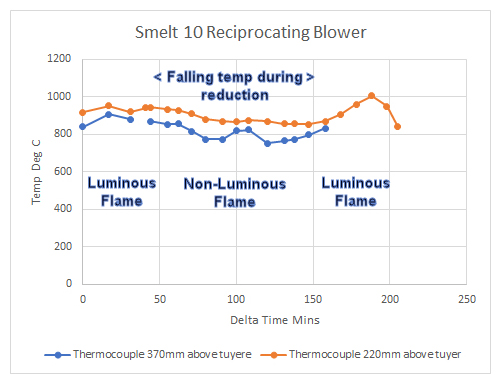

Our latest smelt revealed both the change in colour of the flame as reduction takes place with the flame at the start being yellow and luminous as carbon monoxide is burning away, then fades to a more transparent flame as the ore consumes carbon monoxide during reduction. The flame returns to a luminous state during ‘burn down’ once all the ore has been reduced.

A temperature profile during the smelt shows a general fall in temperature while reduction takes place, as this is an endothermic (takes heat) reaction. This is best seen following the red line which is the thermocouple in the hotter position, closest to the reduction region.

A TV reporter from Meridian News filmed part of the smelt, interviewing me, and also Jeremy Hodgkinson, Jonathan Prus and Judie English the following weekend at the Fernhurst Open Day. You can see the filmed sequence HERE

Our final smelt for the season is scheduled for Saturday 8 October. Should you wish to come, but the weather forecast be wet, check with Tim (01403 710148) on the Friday evening to see if we have had to postpone.

Tim Smith

Click HERE to see a short video of the different stages of the smelt (66.3Mb -Be patient!).